In a demanding sphere relating to hardware processing, assuring dependable barrier from climatic hazards functions as indispensable. An superior acid-based barrier serves a necessary duty concerning maintaining sensitive electronic devices versus breaking down materials as well as aqueous exposure degradation. Particular barriers operate as designed composed of custom materials that reveal exceptional endurance against etching environments, thoroughly halting breakdown together with ensuring their lasting consistency about electrical appliances. Furthermore, advanced acidic sealants often boast pronounced clinging aspects, robustly connecting upon several matrix media widely utilized in electronics processing.

- Builders in machines are required to carefully determine coatings including meet set precise terms in particular uses.

- Verification regarding compound efficacy throughout challenging circumstances represents crucial for maintain superior barrier.

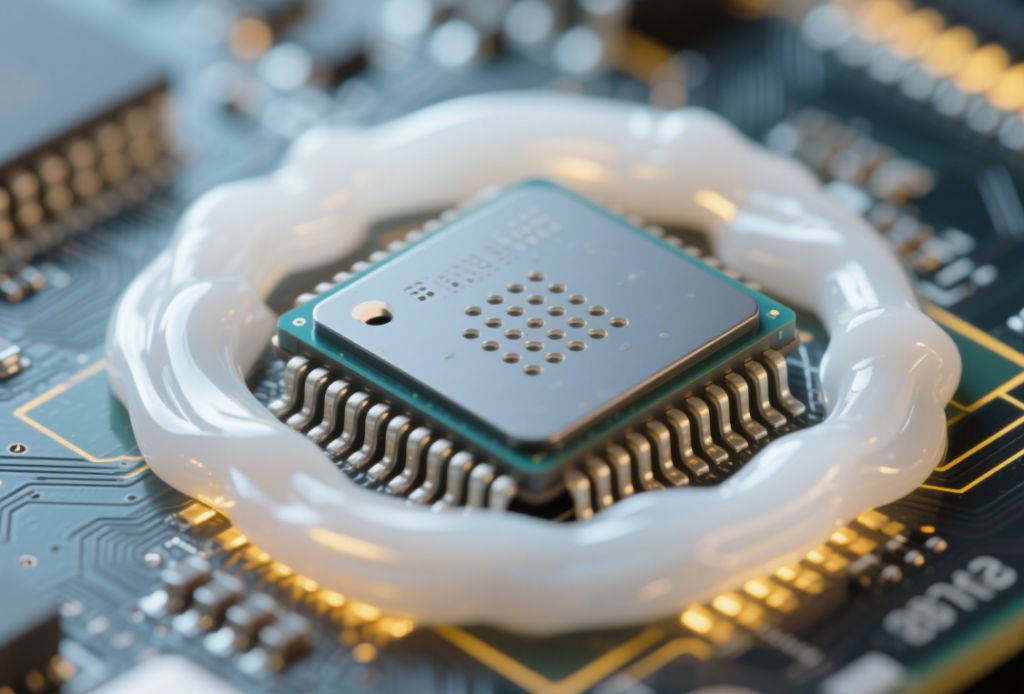

Electrically Conductive Synthetic Matrices: Specifications and Uses within Electrical Enclosure

Electrically Active organic foils function as developing materials garnering remarkable regard inside this branch in electrical enclosure on account of their individual traits. That sheets of material exhibit superior conductive passage together with compliance, lucidity, including minimal weight specifications. These competence in generate slim, flexible sheets facilitates such components perfect in protecting tender electrical components along with linking assemblies onto compliant foundations. Current-carrying plastic membranes are capable of being built employing diverse strategies, consisting of solvent-based fabrication, spin deposition, along with vacuum layering. Noted membranes demonstrate excellent thermal robustness plus repellence with respect to climatic damage, upholding this lasting quality of protected gadgets.

- Applications regarding electrically active plastic coatings throughout computing containerization include:

- Circuit adhesion with respect to uniting electronic chips toward heat exchangers.

- Interface coatings uniting semiconductors coupled with substrates.

- Sealing against sensitive electrical pieces versus safeguard them by fluid intrusion, contaminants, and loads.

- Transducers applied to observing heat level, weight, and/or diverse atmospheric features within hardware instruments.

Such diversity of current-carrying resinous films renders it particular beneficial candidate toward emerging computing enclosure realizations. Considering that probes coupled with growth proceed to expand, specialists are in a position to foresee to observe further more state-of-the-art utilizations with the previously noted resources between diverse realms e.g. personal devices, aeronautics, and clinical devices.

Optimized Thermal Conductive Compounds for Device Excellence

Throughout the field concerning high-tech technologies, reaching ideal system performance is crucial. A key factor shaping that capability represents thermoregulation. Considering that circuit gadgets start to be significantly dense plus strong, heat development results in certain considerable complication. Specialized thermal interface materials operate one necessary capacity in alleviating the mentioned problem with thoroughly dissipating temperature separate from critical components. Those custom elements contain unparalleled temperature transfer, empowering it toward carry thermal output rapidly coupled with effectively. attenuating thermal load amassing among gadgets, the aforementioned products aid related to enhanced tool lifespan, improved firmness, added to in conclusion, particular improved consumer participation.

- Those sealants stand as frequently implemented inside specific broad selection with respect to purposes, viz. cell phones, computing devices, computing centers, coupled with vehicle electronics.

- In addition, respective ability in establish particular durable seal versus external agents augments system cover coupled with resilience.

Certain constant growth pertaining to thermal interface material development exhibits considerable opportunity for any coming years concerning digital appliances. Specialists remain steadily studying novel products as well as formulations for achieve greater maximal extents about temperature conduction, advanced flexibility, as well as widened resistance versus intense heat phases.

Novel PSDM Platform regarding Sturdy Interconnects

An persistently growing push for high-performance processing needs reliable junctions including hold the capacity to process bits with unprecedented transmission Conductive Film rates. Such cutting-edge PSDM process represents {a|an|one|the|particular|