{Meeting rigorous requirements in cryogenic processes requires customized valve design. Our enterprise’s arctic 3-way globular assembly remedies are developed to provide trustworthy performance even at extremely low temperatures, typically below -150°C. These installations offer notable stream direction in subzero substances such as nitrogen, oxygen, and argon, frequently used in industries like LNG, investigative equipment, and therapeutic facilities. We stress long-lasting construction, including minimal-friction fastening elements and rigorous manufacturing, to certify watertight execution. Think about the gains of improving your chilled system with our fresh 3-way round apparatus products.

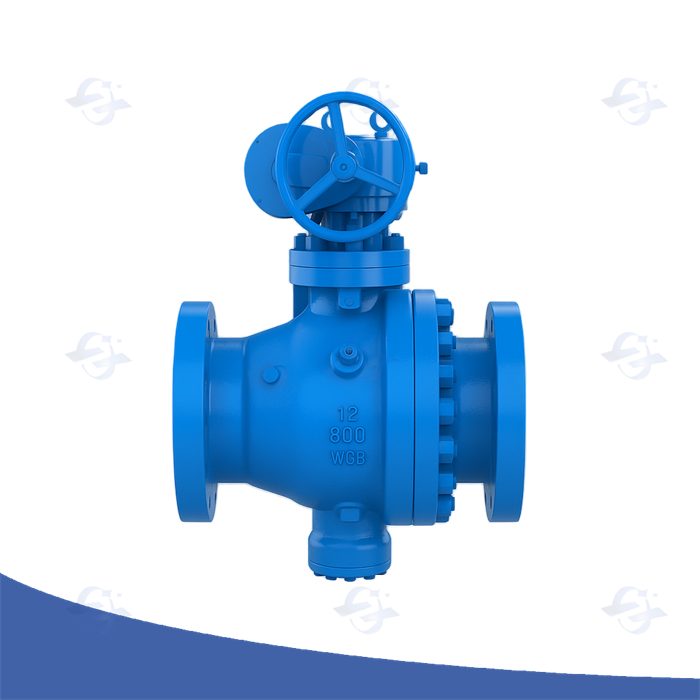

Superior Double Shutoff and Vent Ball Valves

With respect to crucial deployments, particularly where leakage is prohibited, top-tier double block and bleed rotational valves offer distinctive security. This unique design incorporates two separate valve seals, plus a bleed outlet, allowing for validation of the absolute shut-off and discovery of any possible leakage. Frequently employed in mining workflows, refining conversion, and freeze situations, these valves noticeably amplify facility safety and curtail the risk of natural consequence.

Three-Way Chilling Globular Mechanism Design

That formulation of 3-way chilling spherical apparatus presents a distinct engineering difficulty. These valves are usually employed in fundamental industrial operations where rigorous temperatures must be sustained. Key concerns include substance determination, principally regarding embrittlement at minimal conditions, and the essentiality for tight stopping to stop escape of frosty media. Innovative modeling methods and careful fabrication methods are vital to assure trustworthy functionality and lifespan under such challenging functional situations.

Cryogenic Monitor Output in Engineering Applications

That demanding prerequisites of frozen implementations, such as coolant natural petroleum handling and chilled nitrogen storage, necessitate reliable monitor engineering. Integral block purge components provide a particularly robust and effective technique to achieving zero-leak sealing while facilitating periodic maintenance. Their design encompasses a primary regulator with a small escape channel, allowing directed pressure release during sealing and reactivation. This inherent characteristic minimizes persisting commodity entrapment, thereby ensuring outstanding welfare and productivity even under the most demanding working settings. Furthermore, the capacity to watch purge transfer provides valuable assessment facts for process optimization.

Ensuring 3-Way Globe Valve Stopping in Harsh High-Pressure Conditions

Realizing reliable sealing performance with 3-way rotary valves becomes particularly noteworthy when operating within considerable pressure cases. The design must account for significant stresses and potential spillage pathways. Specialized substances, often including advanced metals like rust-resistant steel or exotic alloys, are necessary to withstand the unforgiving conditions. Furthermore, intricate connection geometries and meticulous production processes are vital to minimize compression and guarantee a impenetrable attachment even under fluctuating load cycles. Regular inspection and periodic care programs are too vital for lastingness and consistent operational reliability.

Arctic Ball Valve Leakage Prevention Strategies

Decreasing "discharge" from cryogenic "circular valves" demands a multifaceted "technique". Initial "engineering" considerations are paramount; material "picking" must account for extreme "heat extremes" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "composition", meticulous "development" processes – including stringent weld "assessments" and non-destructive "assessment" – are vital to ensure structural integrity and eliminate voids that could become "escape routes". A "key" component is proper "fitting"; thermal "diminution" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "servicing" – including periodic "examination" for signs of wear and "repair" of any identified issues – is indispensable for maintaining a reliable, leak-tight "joint”. Ultimately, a robust "schedule" incorporating these elements is necessary to ensure the safe and efficient "running" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "waste", safety "hazards", and costly "cessation”.

Double-Layer Block and Escape Tool Check Techniques

To ensure the integrity and safety of critical piping channels, rigorous parallel stopper and drain apparatus check plans are essential. These tests, often mandated by regulatory bodies and industry best standards, typically involve simulating simultaneous closure of two isolation devices while simultaneously ensuring the bleed mechanism remains functional and correctly discharges any trapped material. A common process is to utilize a pressure analysis where the system is pressurized to its maximum working pressure, and the seepage rate around the closed mechanisms is meticulously tracked. The drain component's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of examination results, including any variations observed, is vital for maintaining a reliable function.

Realizing Overall Block Vent Mechanism Operation

To accurately govern force assemblies, a complete recognition of integral block escape component behavior is truly required. These exclusive units primarily work to efficiently expel excess tension from a assembly during pre-determined running stages. A conventional installation consists of a closed section connected to the key force source, empowering a supervised letting out once required. The essential format reduces the risk of over-pressure, preserving both the apparatus and the local vicinity. Regular supervision and maintenance are crucial to ensure optimal operation.

Choosing the Proper 3-Way Ball Valve for Cryogenic Fluids

Choosing a suitable 3-three-ball device for cryogenic processes demands careful assessment of several critical factors. The extremely low thermal drops inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present special challenges. Material picking is paramount; only materials with proven suitability and ductility at these temperatures, such as stainless steel grades like 304L or 316L, or specialized pure alloys, should be assessed. Furthermore, the assembly's sealing functionality is vital to prevent escapes, requiring expert stem sealing formations and low-temperature greases. Finally, pressure ratings and actuation ways, taking into account potential pressure bursts, must be carefully matched to the system's conditions. Neglecting these aspects can lead to disastrous failure and safety jeopardies.

Subzero Circular Valve Material Suitability Catalog

Choosing the appropriate element for cryogenic ball valves is paramount, given the harsh temperatures involved. This compendium highlights common compositions and their reaction when exposed to cryogenic fluids such as solution nitrogen, fluid helium, and oxygen. Stainless steels, particularly classes 304 and 316, often demonstrate adequate sturdiness and corrosion resistance, though martensitic materials require careful consideration regarding vulnerability. Aluminum alloys can be suitable for certain applications, however, their ductility and immunity to specific chemicals needs detailed evaluation. Copper alloys, while offering some positives, may exhibit diminished behavior at these minimal temperatures. Consultation with producers and comprehensive testing is essential to verify stability and welfare in cryogenic tasks.

Optimizing Double Shutoff and Vent Configuration Performance

Realizing optimal performance in double block and bleed arrangements hinges on a multifaceted methodology. Careful inspection of element selection is crucial, with a focus on element accordance and load determination. Regular review of release paths for congestion is indispensable, often requiring the use of expert monitoring instruments. Furthermore, methodology enhancement—including appraisal of movement rates and load contrast—can noticeably enhance overall configuration durability and safety. Finally, observance to fabricator standards and the deployment of a robust upkeep program are essential for long-term performance and endurance.

API 6D Ball Valve

API 6D Ball Valve