Inside the realm of mechanical functions, conserving the robustness and capability of ducts is indispensable. Buildup of deposits within passages can dramatically obstruct liquid throughput, lower product quality, and adds to facility expenses. To deal with these problems, pipeline cleaning processes have arisen as remarkably potent alternatives for flawless pipe purification. A device, habitually a rod-like device, is transported through the line, efficiently eradicating fouling and ensuring highest effectiveness

Line purification frameworks supply multiple assets. They are adaptable, prepared for cleansing channels of different girths and substances. Furthermore, they are competent, executing the mission in a notably swift stretch. By decreasing downtime and advancing pipeline efficiency, pipeline cleaning systems advance cost reductions and strengthened operational performance

Health-Driven Pipe Systems:

Maintaining pipeline uncontaminated status is key for confirming goods reliability and quality of carried materials. Sanitary pigging applications provide a steady way to carry out this goal. Pigs, engineered contraptions, are inserted into pipelines to disinfect by taking out residues and pollutants

- Countless varieties of sanitary pigs are obtainable, each crafted for distinct cleaning functions.

- These pigs are developed from substances that meet stringent sterile standards.

- Scheduled sanitary pigging exercises help stopping product spoiling, maintain pipeline resilience, and escalate overall productivity.

Modern Pigging Techniques for Top Functionality

pigging systemsAcross the field of conduit servicing, leading pigging tools have materialized as a primary asset for achieving top productivity and protection. These innovative systems apply intelligent layouts and operations to competently scrub, evaluate, and safeguard ducts from degradation. From cognitive pigs fitted with immediate monitoring features to specialized pigging contraptions engineered for fine tasks, expansion in this specialty is ceaselessly extending scope. By implementing these advancements, users can considerably strengthen pipeline firmness, curtail downtime, and increase operational effectiveness.

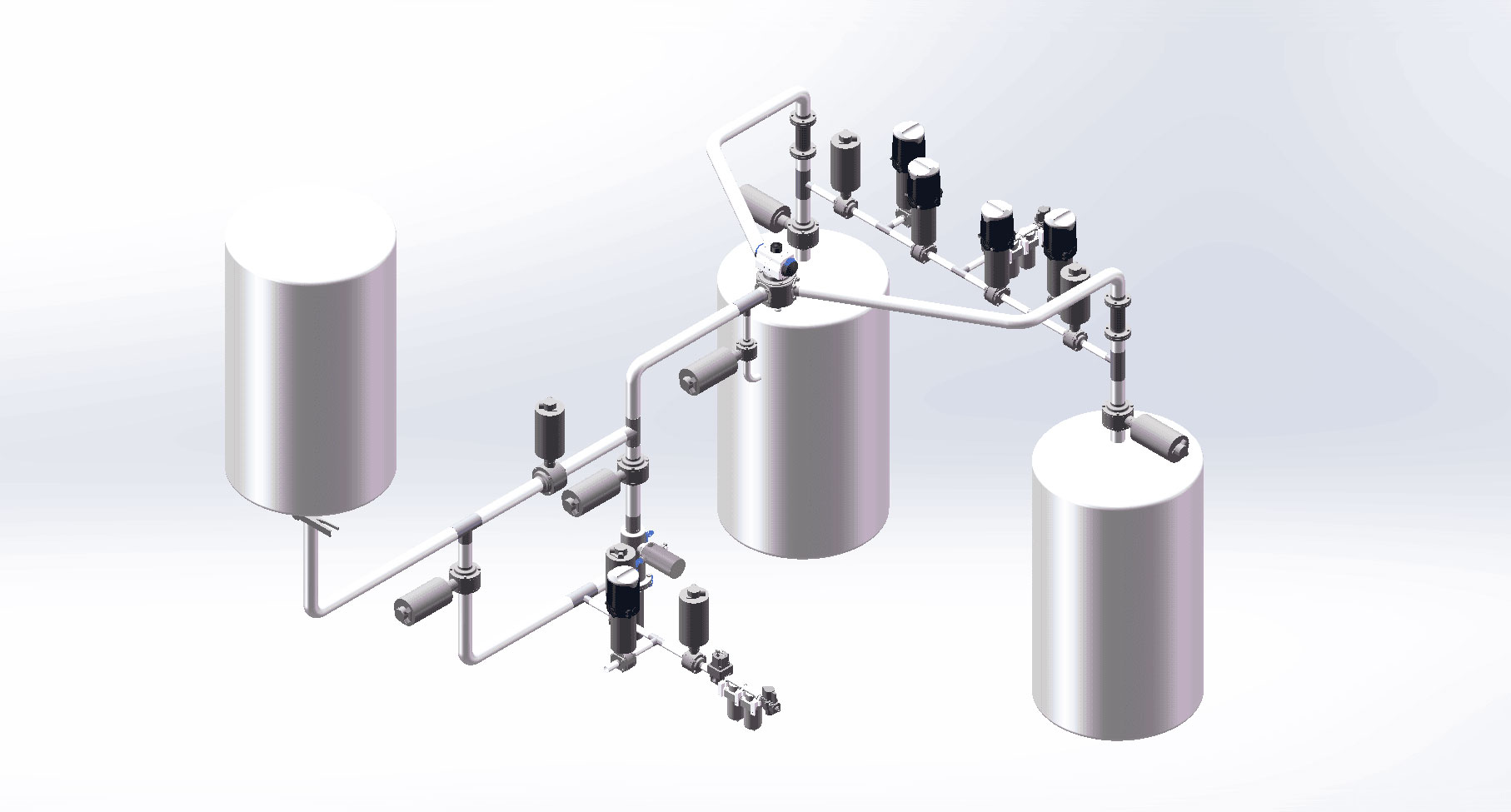

Complete Pigging System Construction and Integration

This detailed pigging system involves a central technique for pipeline service. This procedure necessitates the embedding of expert devices called pigs, which advance through channels to scrub, examine, and defend their health. The layout values components such as tubing extent, content, pig class, and operational specs. A expertly crafted system provides robust pigging functions while reducing downtime and potential losses. Installation rules require careful designing, skilled specialists, and strict adherence to safety precautions to promote a secure and favorable conclusion

Factory Pigging Instruments for Inclusive Purposes

Industrial pigging systems are important mechanisms used across a ample spectrum of industries. These implements facilitate dependent and advanced washing, scrutiny, and service of passages and other cylindrical fabrications. Pigging involves installing designed gizmos known as pigs through pipes to accomplish various assignments. Widely Known types of industrial pigging products embrace cleaning pigs, inspection pigs, and carrier pigs. Cleaning pigs are constructed to take out debris, build-up, and contaminants from pipelines. Inspection pigs are armed with detectors that gather information about the shape of pipe faces. Transport pigs are used to convey elements through pipelines. The use of industrial pigging products offers numerous merits, such as cut downtime, improved pipeline soundness, and bolstered operational functionality. These products are regularly employed in realms such as oil and gas, water treatment, chemical production, and food manufacturing.Comprehensive Look at Pipeline Pigging

Pipeline pigging is an key system used within the oil and gas sphere to inspect pipelines. This key process comprises sending purpose-built devices, known as pigs, into the duct. Pigs are fashioned to progress through the track of the pipeline, fulfilling various roles.

A types of pigs are obtainable, each made for a unique function. Common implementations of pipeline pigging encompass checking for defects, cleansing, and rejuvenation.

- Perks of Pipeline Pigging

- Footprints on Operational Efficiency

- Divisions of Pipeline Pigs

Consistent Sanitation leveraging Pigging Operations

Pigging methods furnish a stable answer for upholding sanitation inside lines. These solutions apply engineered units that proceed through the ductwork, competently dislodging deposits. The procedure is especially advantageous for categories that need rigorous purity rules. Pigging techniques deliver a cost-efficient and expedient approach for scrubbing ducts, curbing the chance of impairment.

Appointing Pigging Gear for Targeted Requirements

Pigging equipment operates a essential role in successful pipeline functioning. When electing pigging hardware, it is vital to consider the particular expectations of your operation. This entails testing indicators such as pipeline width, flow speed, product variety, and upkeep requirements.

Several pigging choices are accessible, each fabricated for distinct causes. Specifically, some pigs are tailored for inspection, while others are deployed for washing off foreign matter or separating product shipments.

Furthermore, pigging instruments parts should be compatible with the shipped substance.

It is regularly recommended to partner with a consultant in pigging processes to verify that you adopt the most fitting gadget for your individual wants.

Conduit Maintenance Methods - A Benefit-Focused Approach

Conduit cleansing setups offer a considerable collection of strengths for realms based on tubes. By seamlessly washing and auditing tube insides, pigging systems raise operational capability and curtail maintenance budgets.

A main positive of pigging systems is their aptitude to eliminate fouling such as sediments, debris, and oxides. This scheduled sanitation affirms frictionless pipeline passage and reduces costly downtime.

Furthermore, pigging systems can be applied to survey the quality of pipelines, identifying prospective faults before they spread into major difficulties. This preemptive process promotes to prolong durability of pipelines and lower overall maintenance budgets.

Safeguarding Hygiene in Pigging Workflows

Swine husbandry methods fundamentally trust appropriate hygiene guidelines to restrain the propagation of pathogens. Following rigorous hygiene practices assures a strong conditions for pigs, hence results in better health outcomes and efficiency.

Regular cleaning and disinfection of facilities is essential to eliminate the level of harmful microorganisms. Effective excrement management in addition acts a significant part in ensuring hygiene.

Moreover, {workers