Launching this overview centered on rigorous facial refinement methodologies supporting assembly sectors

Achieving predictable consequences within their assembly operations? Exquisiteness refinement solutions perform as vital supporting reaching superior part quality together with improved capability. This organization offer such extensive array including sophisticated methods, covering electrochemical finishing, lapping, along with milling, capable of address even the most required functions. The dedicated specialist team partners with stakeholders to create adapted processing approaches devised to maximize surface elements and guarantee exact cohesion. In the end, these careful systems contribute to lower spending and amplified productivity for your company.

Fundamental Weld Treatment Styles & Utensils

Correct connection maintenance is genuinely vital for guaranteeing the stability of any formed connection. That operation removes impurities, porosity, and other foreign materials that can damage stability. Diverse techniques exist, including handheld chipping with scraper tools, and engine-driven scraping. Focused equipment, such as mobile pneumatic sanders, small scalers, and oxide systems, are frequently applied for more productive results, particularly on expansive welds. In addition, organic preparations can be utilized to further extract stubborn impurities. Electing the most effective technique and paired instruments depends on the manufacturing matter, extent, and intended condition.

Comparable Concepts:

- Formation Scrutiny

- Manufacturing Study

- Construction Care

Forming De-Flashing: Methods & Solutions

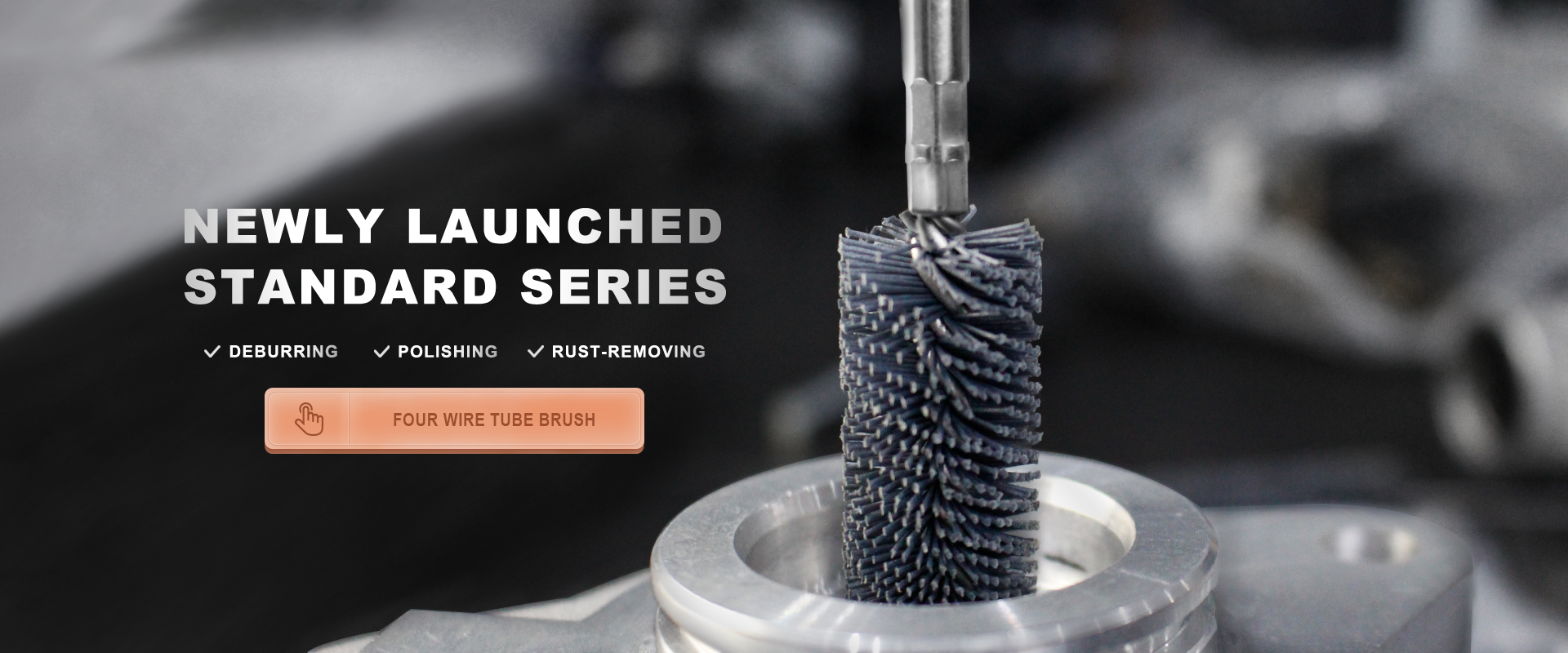

Attaining a smooth, functional surface on fabricated parts is crucial, and deburring plays a vital contribution in that process. Primarily, this was a manual, effortful task, but modern molding operations increasingly leverage advanced burr-reducing methods. These strategies range from simple instrumental brushing and grinding to sophisticated automated systems employing computerized deburring stations and even abrasive jetting techniques. Ultrasonic detergent-free cleaning offers a careful solution for delicate elements, while flame deburring is frequently used for strengthened compounds. The selection of the appropriate burr elimination process depends significantly on the component, part form, and desired surface finish. What's more, understanding the reason of burr formation—often related to die design or creation parameters—can help mitigate them altogether.

Electrolytic Strip Brush Applications

Conductive polishing strip implements find extensive utility across a array of industries, largely due to their gentle yet effective action. Specifically, they excel in removing tenacious burrs from stamped metal elements, preparing bases for subsequent treatment processes like powder application. Beyond deburring, these brushes are frequently used for exact surface treatment prior to welding, offering a superior alternative to abrasive tactics that can introduce surface blemishes. Furthermore, their ability to rigorously remove scale and oxides makes them valuable in upkeep operations on enormous equipment.

External Refinement for Critical Components

Reaching optimal performance and amplified longevity for critical machine pieces frequently necessitates specific surface refinement systems. This isn't merely about aesthetics; it’s about altering the subtle structure of the compound to reduce resistance enhance decay resistance, and improve aggregate functionality. Diverse approaches, including shining, plating, and light texturing, can be precisely applied depending on the precise application and the targeted outcome. The selection of a particular refinement method must always consider the component's properties and the performing environment to avoid unintended consequences and improve the component's robustness.

Computerized Solder Clearing Processes

The call for consistently high-quality welds in modern generation environments has spurred significant advancements in joint post-processing techniques. Digital removal platforms are rapidly gaining popularity as a option to traditional, labor-intensive methods like abrasive blasting or manual grinding. These advanced systems often incorporate technologies such as laser cleansing, high-pressure waterjet scraping, or specialized abrasive substance, ensuring efficient and precise slag extraction without damaging the underlying link. Implementing these intelligent solutions leads to reduced labor costs, improved security, and a more consistent look that directly impacts the structural integrity capability of the final component. The ability to integrate these equipment into existing processing lines further enhances their appeal across a wide range of industries, including construction and fabrication.

Deburring Molds for Maximum Work

In an effort to secure excellent results from your castings, removing burrs is a vital procedure. Protrusions, a regular byproduct of the shaping system, can affect work, bring about stability complications, and negatively impact surface finish. Therefore, thorough deburring – which may involve manual techniques or automated systems – is imperative for producing a distinguished processed output qualified for its planned assignment. This method exclusively increases operation but also minimizes the imminent for error.

Clear-cut Disinfection with Band Sweeping Methods

Achieving high-quality refreshment in high-requirement production sectors often requires specialized solutions. Ribbon polishing systems offer a powerful option to dispose of residue from complex facets. These advanced techniques utilize engineered tools to provide continual application – crucial for precision disinfection and confirming component grade. Examine the benefits of wipe wiping techniques for your next purification undertaking.

Electric Cleaning for Welds & Surfaces

Electrochemical cleansing offers a efficient method for processing welds and various element forms. This process, fundamentally engaging electrochemistry, eliminates oxides, scale, trace welding fumes, and other foreign bodies that can hinder next processes like painting, examination, or further fabrication. Unlike abrasive strategies, electrolytic polishing provides a light action, minimizing injury to the base matter and leaving a remarkably spotless surface. It's especially worthy for complex forms and constricted areas where manual cleaning would be inadvisable. A carefully monitored electrolyte preparation and electrical current are mandatory for achieving uniform results.

State-of-the-art Foundry Deburring Systems

Beyond traditional physical deburring, modern casting facilities are increasingly employing progressive processes to achieve consistent edge finishing. These improved deburring approaches often involve a combination of automated tools and precisely controlled standards. Abrasive deburring, for instance, offers exceptional accuracy and allows for detailed geometries to be flawlessly cleaned, minimizing fabric removal and maximizing product integrity. Furthermore, digital deburring cells, utilizing rotating tools, are becoming universal, providing increased throughput and stable results, particularly for high-volume production runs. The selection of the appropriate surface cleaning method depends heavily on the manufacturing compound, product geometry, and desired appearance characteristics.

State-of-the-art Precision Polishing and Band Brushing Methodology

The constant pursuit of surface superiority in modern manufacturing demands ever more specialized processes. Among these, precision coating utilizing band brushing technology stands out as a effective solution. This approach, frequently employed across diverse industries like transportation, offers distinct advantages in achieving reliable material wear, perfecting, and smoothing results. Unlike traditional systems, strip sweeping technology allows for highly controlled material reduction and the ability to access intricate geometries with a measure of accuracy previously unattainable. Furthermore, advancements in brush option and system configuration continue to expand the powers of this essential buffing strategy.

honing brush

honing brush