Transportation manufacturers request the highest benchmarks of precision in sections. A critical aspect is achieving a impeccable appearance on indented closures, which can be difficult with traditional techniques. Our pioneering Precision Dished EndAC Polishing Machine solves this obligation by presenting an automated and rigorous answer. This instrument employs dedicated tooling and a regulated polishing technique to achieve a glossy finish on indented closures, maintaining optimal efficiency and toughness of automotive parts.

- The gadget’s programmable interfaces provide for precise modifications to the polishing conditions, ensuring reliability and echoing.

- Its compact configuration improves workspace productivity while curtailing operator stress.

- Incorporation with existing manufacturing workflows is smooth, simplifying production lines.

Robust Tank Polishing Machines for Stainless Steel Fabrication

In the realm of stainless steel production, obtaining a unblemished and mirror coating is critical. To fulfill this feat, high-efficiency tank polishing machines have developed as necessary apparatuses. These high-tech machines utilize cutting-edge technology to precisely wipe out surface irregularities and increase a sparkling sheen on stainless steel tanks.

- Moreover, high-efficiency tank polishing machines are built for optimal capability, incorporating durable construction, solid motors, and creative polishing heads that curtail surface damage.

- Consequently, fabricators can attain exceptional results with minimal effort, enhancing their production operations and providing high-quality tanks that adhere to the stringent criteria of various realms.

Modern Cylindrical Polishing System for Precision Engineering

The urge for exceptional surface excellence in precision engineering is constantly spreading. To confront these rigorous prerequisites, a novel cylindrical polishing system has been developed. This advanced technology utilizes cutting-edge strategies to secure unparalleled surface uniformity. It skillfully excises imperfections and strengthens the overall capability of cylindrical pieces across a wide range of areas.

- Gains include increased yield, reduced manufacturing charges, and improved product stability.

- The system is engineered to handle a diverse range of materials, including metals, ceramics, and plastics.

- Handlers can easily regulate the polishing controls to reach the desired quality.

This advanced cylindrical polishing system represents a significant breakthrough in precision engineering, allowing manufacturers to produce segments of exceptional value and productivity.

Innovative CNC Polishing Solutions for Complex Shapes

Obtaining a flawless sheen on intricate units can be a complex task. Traditional polishing techniques often struggle to realize consistent results on complex profiles, creating time-consuming cycles. However, the advent of high-tech CNC polishing solutions has improved the industry, facilitating manufacturers to achieve unprecedented standards of accuracy and efficiency.

These sophisticated systems apply programmed machining technology to thoroughly finish surfaces with minimal operator intervention. Equipped with advanced spindles and a variety of polishing tools, CNC machines can effortlessly handle even the most demanding patterns.

Besides, these solutions offer enhanced control over specifications such as pressure, speed, and tool path, promoting consistent results across different materials and complexities.

- Benefits of automated CNC polishing include:

- Augmented precision and surface smoothness

- Cut cycle times and production costs

- Optimized product consistency and repeatability

- Increased design flexibility for complex shapes

Rugged Tank Polishing Machine for Industrial Applications

For demanding industrial settings where functionality is paramount, a high-torque tank polishing machine is an vital tool. These machines are specifically crafted to handle the stresses of repeated operation in severe environments. Equipped with durable construction and high-torque motors, they can effectively clear rust, paint, and multiple contaminants from tank surfaces, conferring a smooth and sanitary finish. A variety of accessories are available to accommodate different tank sizes and layouts, making them versatile for a wide range of applications.

A Dished End Polishing System with Adaptive Control

Our leading Dished End Polisher features automated Adaptive Control Technology to deliver unparalleled output. This innovation continuously observes the polishing process in real time, guaranteeing optimal surface smoothness for a wide range of ingredients. The Adaptive Control Technology optimizes the adjustment of key criteria, such as pressure, speed, and oscillation, to achieve consistent results every time.

- Gains include:

- Elevated surface finish quality

- Minimized polishing time

- Elevated control over the polishing process

- Versatility for a range of materials and applications

CNC Polishing Machine for Surface Finishing and Refinement

A CNC polishing equipment is a advanced tool utilized in various sectors for securing distinguished surface finishes. These machines leverage computer numerical control (CNC) technology to accurately polish surfaces, getting rid of imperfections and establishing a smooth, refined appearance. The robust design of CNC polishing machines permits for varied output.

- Manufacturing processes

- Alloys

- Improving feel

The high-tech nature of CNC polishing machines ensures reliable results, cutting human error and improving efficiency. By harnessing a variety of devices, these machines can finish a wide range of surface kinds and elements.

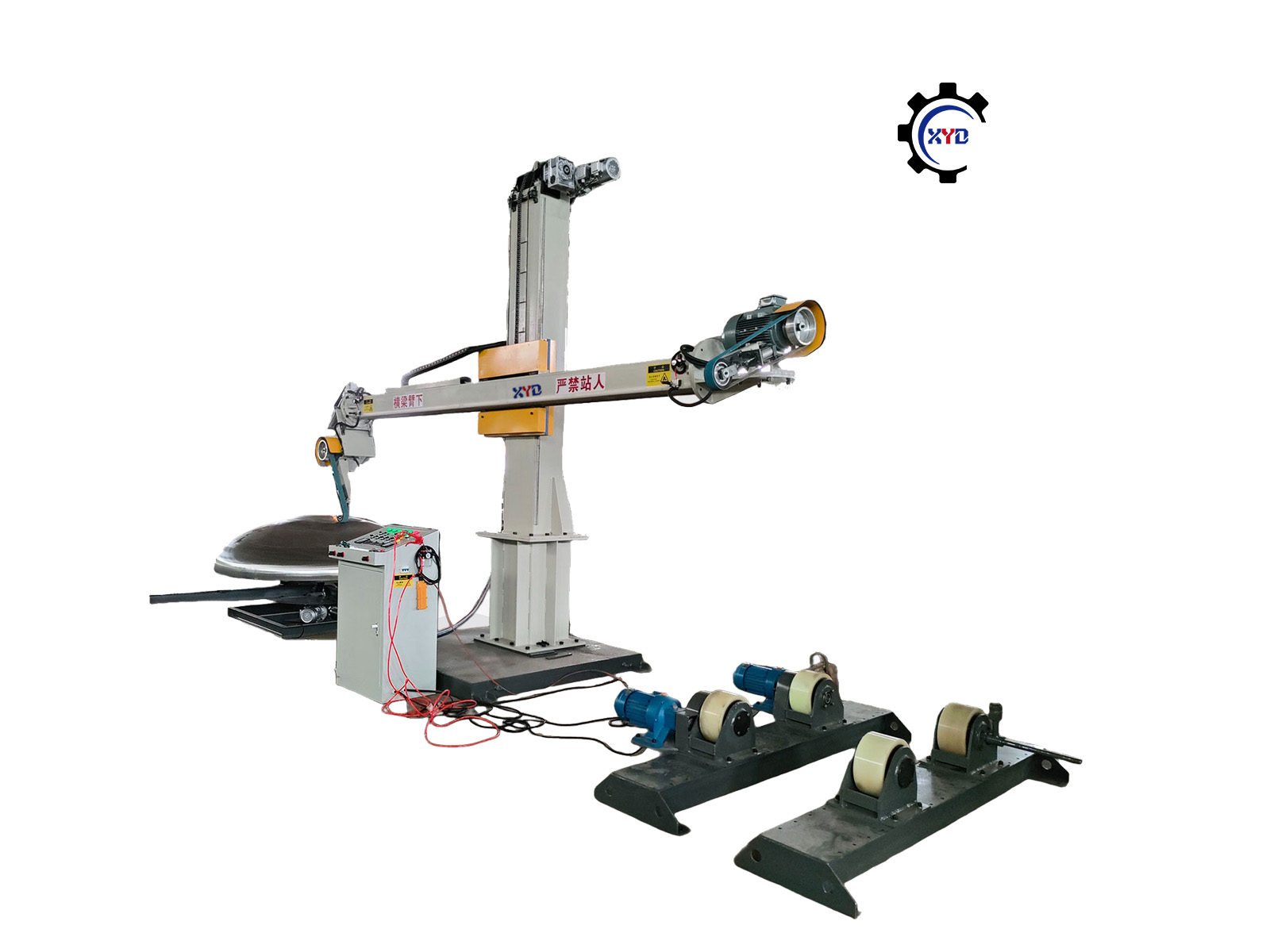

Heavy-Duty Cylindrical Finishing Machines

Assembling and treating large diameter cylindrical sections often involves specialized equipment. These machines are constructed to generate precise parameters on objects with significant girth, making use of a variety of abrasive materials.

The choice of cylindrical polishing equipment depends heavily on the specific application and desired outcome. Some common types include horizontal lathes, each offering distinct advantages for smoothing surfaces.

- Workholding systems are essential to securely hold large diameter pieces throughout the polishing process.

- Modulating abrasive intensity are critical for producing consistent results.

Accelerated Dished End Polishing Machine for Mass Production

In modern quickly evolving manufacturing industry, the push for high-performance high-volume production operations is essential. To satisfy this expectation, manufacturers are leveraging cutting-edge technologies like high-speed dished end polishing machines. These high-tech tools deliver exceptional accuracy in a time-sensitive manner, ensuring consistent quality and first-class surface finishes for a comprehensive range of components.

Built to handle large production runs with unprecedented speed, these machines make use of advanced polishing techniques to generate one-of-a-kind finish required for demanding applications. Essential features include high-speed spindles, intelligent control systems, and innovative sheening pads that work in synergy to maximize capability.

Besides, these machines often incorporate automation capabilities for increased capacity and reduced labor costs. This combination of speed, accuracy, and mechanization makes high-speed dished end polishing machines a vital asset for manufacturers striving to perfect their production processes and fulfill the growing pressures of the market.

Exact CNC Polishing for Aviation and Therapeutic Devices

In the challenging fields of aerospace and medical device manufacturing, surface excellence is crucial. CNC polishing grants a highly meticulous and reliable method to generate the exacting surfaces required for these critical applications. By deploying advanced CNC machining technology, manufacturers can create surfaces with exceptional polish, detail, and sturdiness. This process enables the production of components that adhere to stringent standards for capability, reliability, and security.

- criteria needs criteria cnc polishing machine needs criteria

- Furthermore, CNC polishing raises the corrosion resistance and biocompatibility of products used in aerospace and medical devices.

- Thereupon, it plays a vital role in extending the lifespan and enhancing the effectiveness of these products.

Versatile Cylindrical Polishing System for Customization

Unveiling a revolutionary system to cylindrical polishing: the Modular Cylindrical Polishing System. This cutting-edge system empowers unparalleled customization, specializing to your specific specifications. With its flexible design, you can easily adjust the polishing heads, parts, and parameters to deliver the optimal finish for your cylindrical objects.

- expectations preferences needs

- Strength1

- Merit2

- Benefit3